ULMA Inoxtruck designs and manufactures material handling equipment for clean rooms. They supply innovative solutions for the food industry as well as the pharmaceutical, medical, microelectronics and aeronautic clean rooms. ULMA Inoxtruck produces material handling equipment following the guidelines of hygienic designs that are required by the Good Manufacturing Practices (GMP) for the processing and packaging lines.

SOLUTIONS FOR FOOD INDUSTRIES

HYGIENIC SOLUTIONS FOR LOAD HANDLING IN CLEAN ROOMS

Hand Pallet Truck

Nominal capacity 1500-2000 kg

‘Cleanable solution for goods transport’

The MPT 2013 Series hand pallet trucks are specially designed to handle fish, dairy product, meat, fruit and vegetable in aggressive environments in the food and agricultural sector guaranteeing strict hygiene compliance in this highly demanding area. Read more

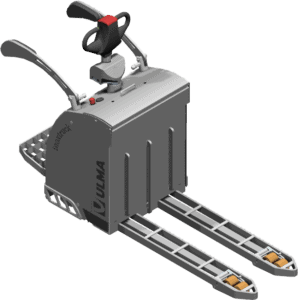

Electric Pedestrian Pallet Truck

Nominal capacity 1600-2500kg

‘High productivity with hygienic design’

The ULMA Inoxtruck 100% stainless steel electronic pedestrian pallet truck provides innovative and hygienic design, ideal for fish, dairy product, meat, fruit and vegetable in aggressive environments in the food and agricultural sector guaranteeing strict hygiene compliance in this highly demanding area. Read more

Electric Scissor Highlifter

Nominal Capacity 1000kg

‘Hygienic and ergonomic working Table’

ULMA Inoxtruck electric scissor highlifter offers an innovative design to improve the ergonomics in the handle of fish, dairy product, meat, fruit and vegetables and the load keep always to the suitable height to collect/deposit them and reducing the effort. Read more

Electric Platform Pallet Truck

Nominal Capacity 2000-2500kg

‘Long distance goods transport in harsh environments’

The ULMA Inoxtruck 100% stainless steel electronic paltform pallet truck provides innovative and hygienic design, ideal for fish, dairy product, meat, fruit and vegetable in aggressive environments in the food and agricultural sector guaranteeing strict hygiene compliance in this highly demanding area. Read more

Electronic Pedestrian Stacker

Nominal Capacity 1000-1200 kg

‘Maximum hygiene at load stacking’

ULMA Inoxtruck electronic pedestrian electronic stacker provides a hygienic and innovative design, solving all needs for the stacking and the storage of fish, dairy product, meat, fruit and vegetable at different heights. These 100% stainless steel electronic stackers offer a residual load capacity at maximum height. Read more

Manual Stacker Mini-Load

Nominal Capacity 200kg

‘Frontal and side reel ergonomic and safe handling’

Cleanrooms are environments of low temperatures and high humidity, therefore the manual handling of loads is a hard job that may cause possible injury. The 100% stainless steel and cleanable manual Mini-Load Stacker ULMA Inoxtruck, solves this problem, enabling ergonomic and easy handling meat, fish, dairy product, fruit and vegetable.Read more

Electromanual Mini Load Stacker

Nominal capacity 200 kg

‘Minimum effort for roll handling at height’

The 100% cleanable Electromanual Mini Load stackers with electric lifting system are designed to handle rolls, boxes, tilting attachments or other implements in production clean rooms and packaging lines of meat, fish, dairy, fruit and vegetable. Read more

Electromanual Maxi Load Stacker

Nominal capacity 600 kg

‘High load capacity at height’

The 100% cleanable Electromanual Maxi Load stackers with electric lifting system are designed to handle rolls, boxes, tilting attachments or other implements in production clean rooms and packaging lines of meat, fish, dairy, fruit and vegetable. Read more

Bottom Roll Trolley

Nominal capacity 1500-2000 kg

‘Ergonomic solution for bottom roll handling’

This innovative trolley has been designed and manufactured by ULMA Inoxtruck to make the hard task of replacing the film rolls of the machines for wrapping/packaging meat, fish, dairy product, fruit and vegetable. Read more

Electromanual Tilter EBT10

Nominal capacity 1000 kg

‘Maximum ergonomics at load tilting’

ULMA Inoxtruck EBT10 tilters allow an ergonomic handling/casting of loads, thanks to the tilting system of 85º and 105º. These models have an innovative design that makes possible an ergonomic handling/tilting to conveyor belt or other containers of products of fish, dairy, meat, fruit and vegetable industry reducing efforts. Read more

Electromanual Tilter EBT300

Nominal capacity 300 kg

‘Maximum ergonomics at load tilting’

The ULMA lnoxtruck tilters, specially designed for the industry of seafood, meat, vegetables and dairy products are mobile models developed for effective turning /casting of containers, euro bins and drums to conveyor belts or working tables.